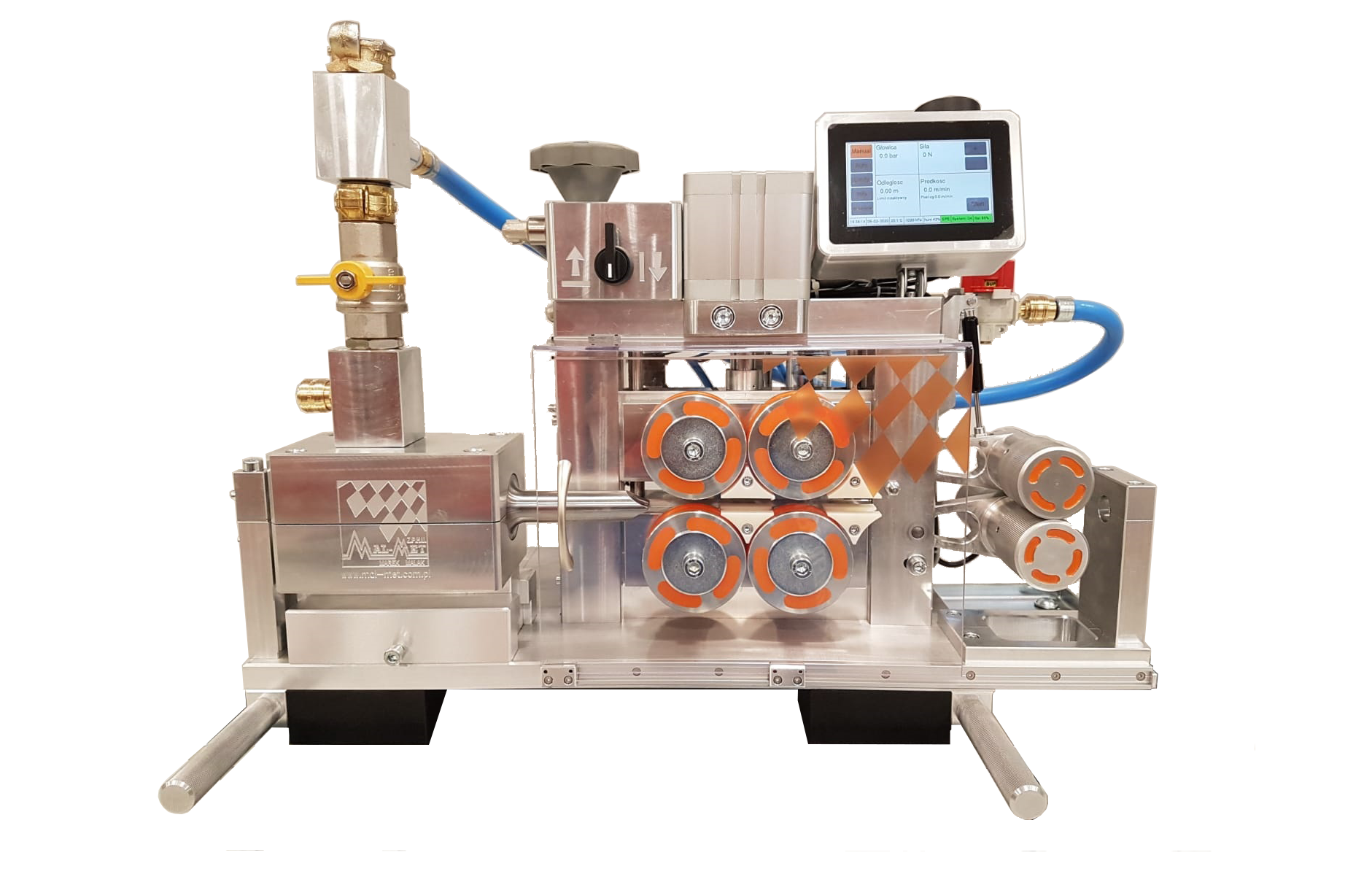

MAH-4 Uniwersal Elektronik

MAL-MET

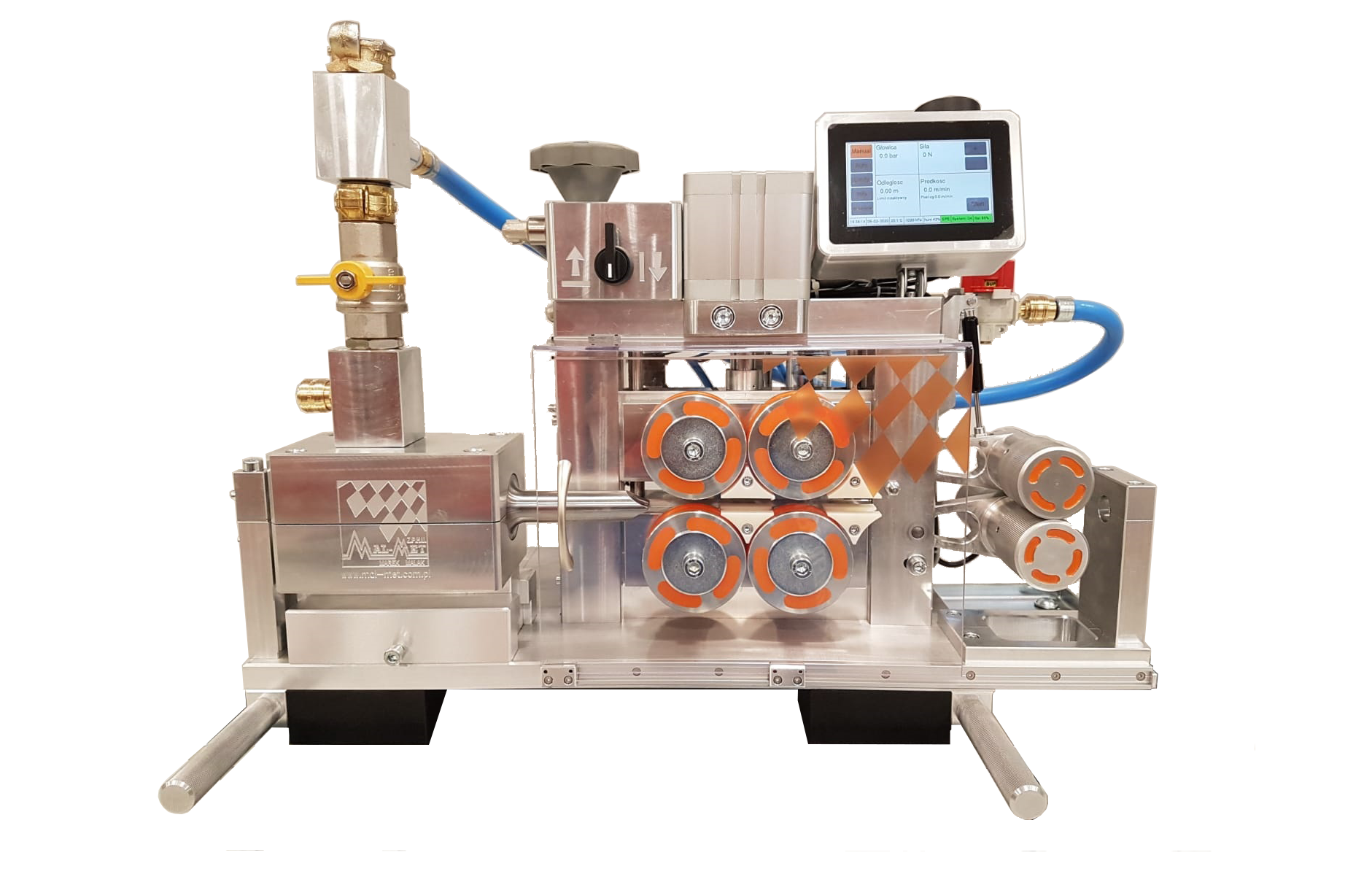

The most modern model of fiber optic blowing machine. MAH-4 Universal Elektronik is designed for all fiber optic diameters from 1 mm to 17 mm. The automation in our blowing machines means continuous control over the optical fiber.

read more

NEW

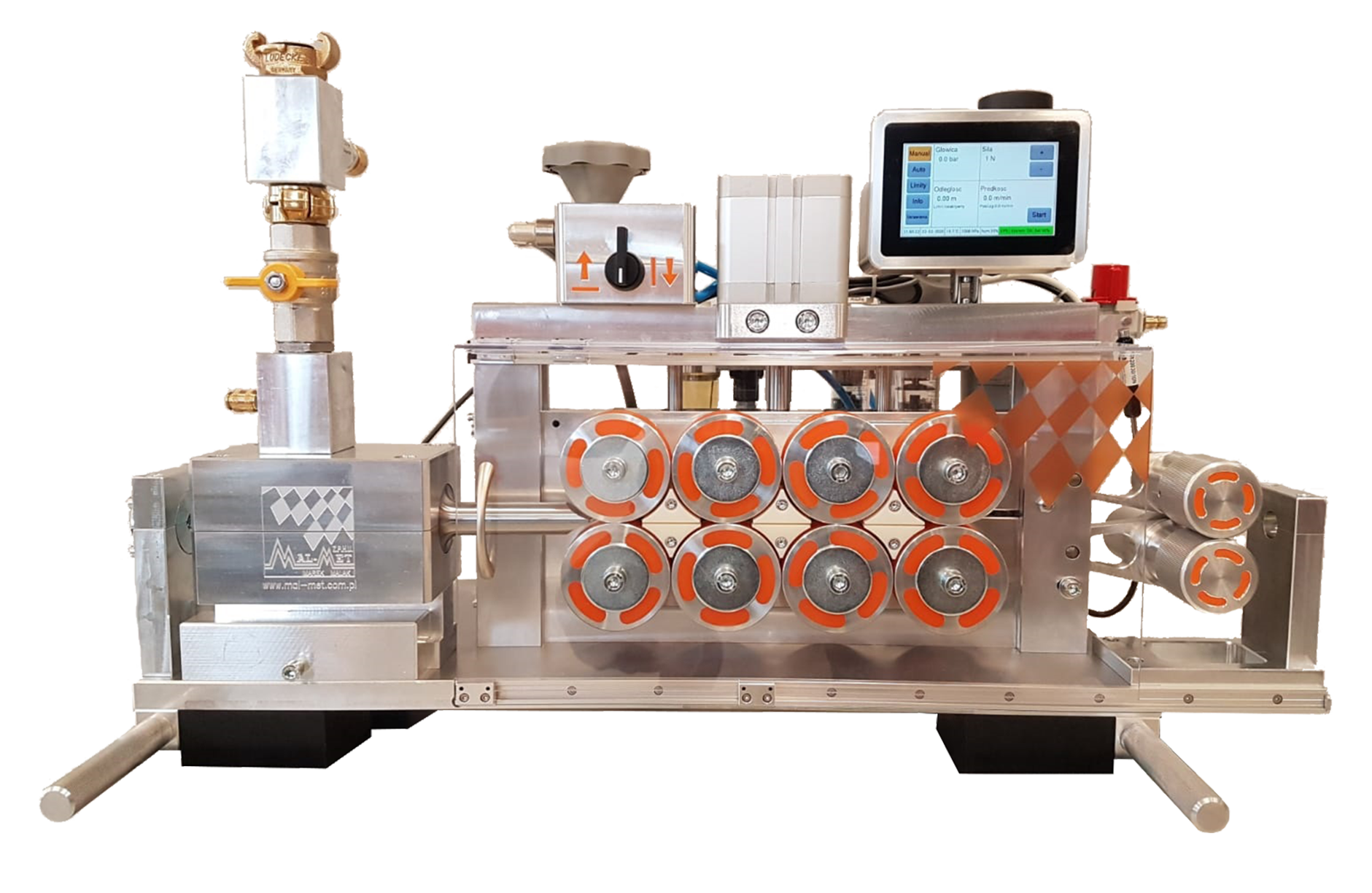

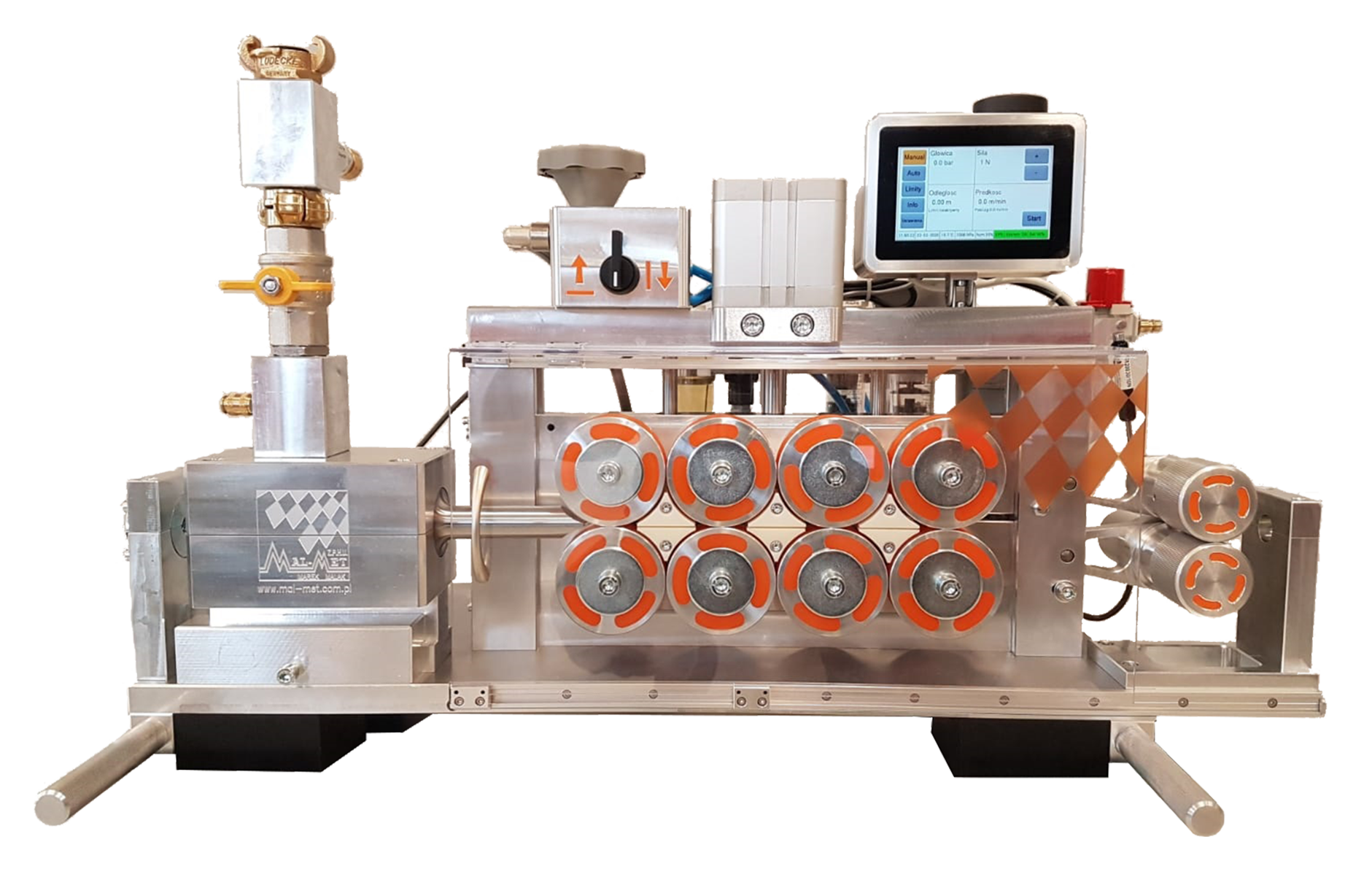

MAH-4 Elektronik

MAL-MET

The most modern model of fiber optic blowing machine. The MAH-4 Elektronik model is the most powerful model designed for longer routes and for optical fibers with a diameter of 3 mm to 17 mm. The automation in our blowing machines means continuous control over the optical fiber.

Read more

NEW

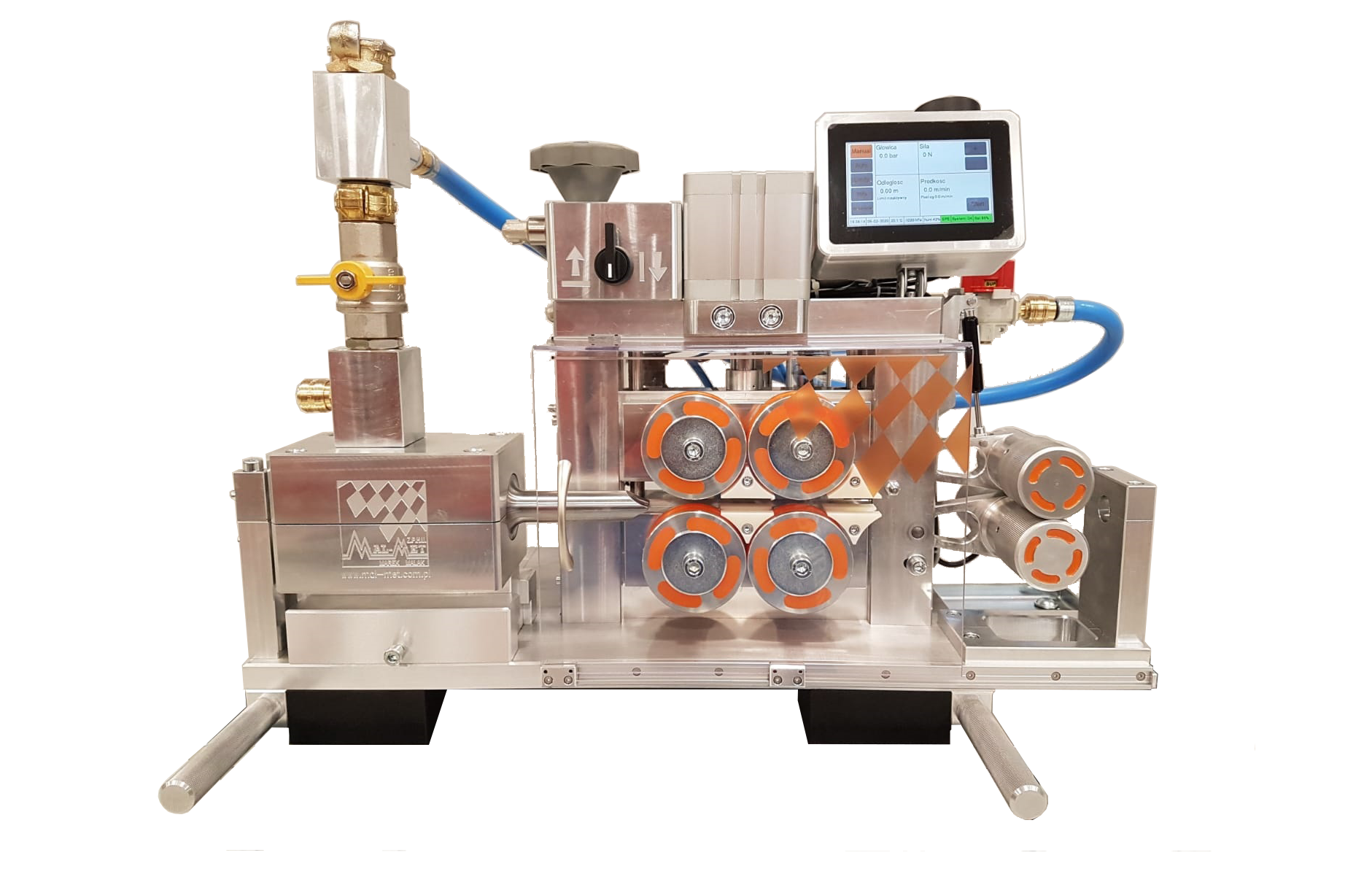

MAH-4 Mini Elektronik

MAL-MET

MAH-4 Mini Elektronik is the newest blowing machine for optical fiber cables on the global market. It is characterized by a monolithic construction and at the same time incredible sensitivity and precision, both in terms of workmanship and control over the cable being blown.

READ MORE

NEW

MAH-4 Uniwersal Elektronik

The most modern model of fiber optic blowing machine. MAH-4 Universal Elektronik is designed for all fiber optic diameters from 1 mm to 17 mm. The automation in our blowing machines means continuous control over the optical fiber.

READ MORE

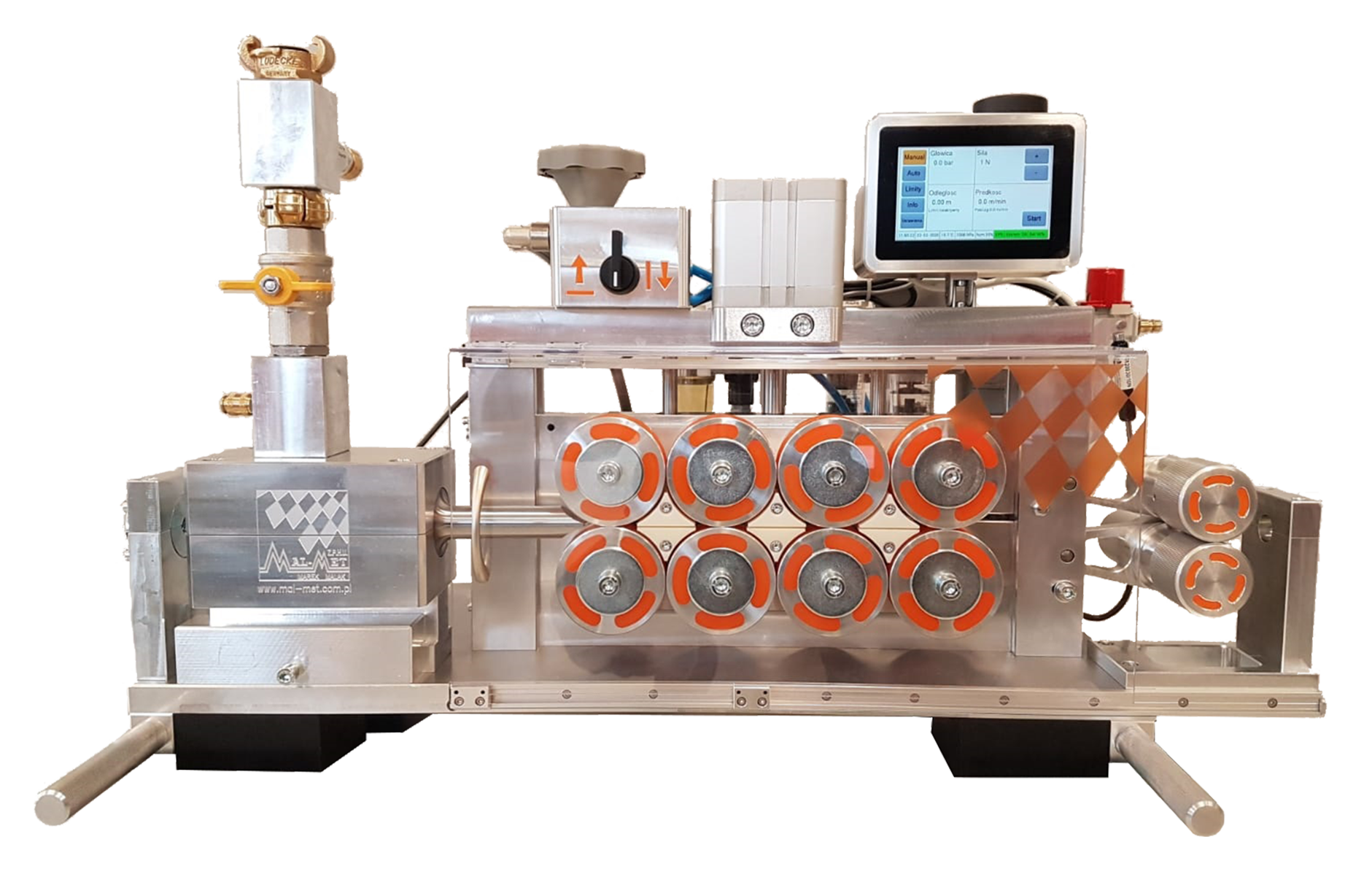

MAH-4 Elektronik

The most modern model of fiber optic blowing machine. The MAH-4 Elektronik model is the most powerful model designed for longer routes and for optical fibers with a diameter of 3 mm to 17 mm. The automation in our blowing machines means continuous control over the optical fiber.

Read more

MAH-4 Mini Elektronik

MAH-4 Mini Elektronik is the newest blowing machine for optical fiber cables on the global market. It is characterized by a monolithic construction and at the same time incredible sensitivity and precision, both in terms of workmanship and control over the cable being blown.

READ MORE

MAH-4 Mini Kosa

The latest model of the blowing machine from MAL-MET. The machine is standardly equipped with automation and parameter recording, as well as all technical innovations offered by our company.

READ MORE

FIBER OPTIC BLOWERS

Manufacturer of fiber optic blowing machines

MAH-4 capabilities

MAH-4

We offer promotional prices and free help for new open business

Latest videos

Fiber blowing machines models

Carousel for optical fibers and cables

Presentation

Our customers

FIBER OPTIC BLOWERS MAL-MET

MAH-4 models will be equipped with:

- intelligent touch controller

- two modes of operation: manual – allows you to operate the so-called manual – i.e. the operator controls the settings during operation, automatic – after entering the appropriate data and activating the automatic mode, the machine independently controls the cable feeding process with the appropriate force and prevents damage to the fiber optic cable.

- injection parameters registration: effective force on the cable measured in Newton (N), fiber wearing pressure (bar), injection speed (m / min), injection length (m),

- creating a graph while the machine is working

- GPS location of the machine on the map

- reading weather conditions – temperature, atmospheric pressure (Hpa), humidity (RH%)

- wireless connection of the machine with auxiliary equipment such as tablet, laptop, telephone, etc., date and time

- handling the blowing report is done using a web browser with prepared information tables.

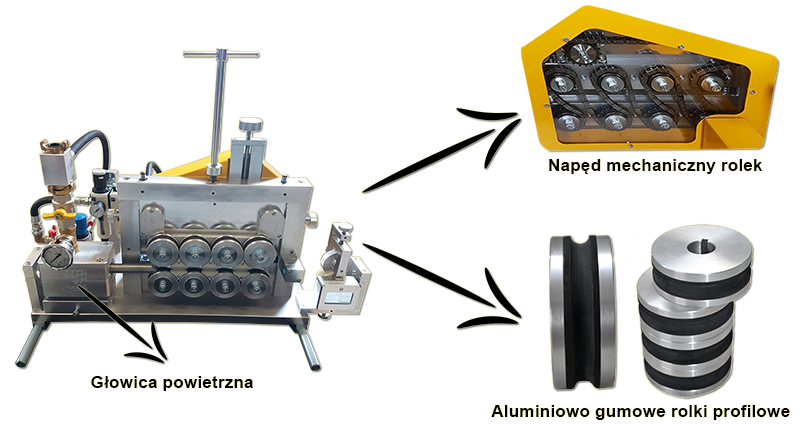

The machines can be equipped with 4 different models of heads.

- The basic head is used for blowing cables and microducts.

- Micro head, as the name implies, for blowing micro cables pasta.

- Y head cables and pipe packages, it is possible to blow another cable or pipe to the existing installation in one direction.

- Head X cables and pipe packages, gives the possibility of blowing another cable or pipe to the existing installation in two directions, i.e. with so-called looping.

Model configurations:

- MAH-4 Electronics – cable and pipe range from 3 to 17 mm, HDPE pipe range from 5 to 50 mm.

- MAH-4 Universal Elektronics – range of cables and pipes from fi 1 to 17 mm, range of duplicates from fi 7 to 50 mm.

- MAH-4 Package – cable and pipe range from 3 to 35 mm, HDPE pipe range from 7 to 50 mm. Pipe packages in the range up to 35 mm.

Each machine is with touch controller, as a option you can add:

– report recorder and chart creation (collect all data from the blowing process ready for printing in tables and charts)

– full automatic operation (machine itself operate full blowing fibre process)

The machines can be equipped with 4 different models of heads:

Micro head: as the name suggests, for blowing micro cables pasta.

Basic head: used for blowing cables and microducts.

Y head: cables and pipe packages, gives the option of blowing another cable or pipe into an existing installation with one or two cables in two directions with so-called overlapping,

X head: cables and pipe packages, it is possible to blow another cable or pipe into an existing installation with two or more cables in two directions with so-called looping.

Fiber optic blow molding machines for MAH-4 Uniwersal Elektronik, MAH-4 Elektronik and MAH-4 Pakiet are fully professional machines for inserting and blowing microcables, optical fibers, copper cables, etc. in the secondary pipes. The most important advantages of blow molding machines are its patented construction and construction as well as the technology of its implementation. Blow molding machines are manufactured in Poland from scratch at MAL-MET in the latest CNC technology and have a CE declaration of conformity. Based on the opinions of our customers and taking into account the tests carried out, our blow molding machines are the most powerful among the available fiber and fiber blowing machines on the world market. We obtained this result by using the best materials in the production as well as the well thought-out and patented design of the machine.

The most important features of fiber optic blowers manufactured by us are:

- Versatility – The scope of operation of the blow molding machine allows the insertion of cables from 1 mm to 35 mm and the use of all duplicates used in this industry.

- Reliability – The reliability of the blow molding machine is influenced by factors such as the patented design, accuracy of manufacturing technology, a large number of bearings, selection and use of the highest quality materials in production.

- Speed – The blow molding machine inserts approx. 110 m cable per minute.

- Power (strength) – Thanks to the arrangement of profiled rollers that wrap the cable in 90%, we can introduce it with high force and speed, and at the same time avoid slipping of the cable or even its chafing (damage) or breakage. In addition, each roller has its own drive, which is transmitted through a pneumatic gear motor.

- Operating method – The machines have a legible and easy to use touch screen. The machine can be equipped with automatics thanks to which the blower controls the fiber optic injection process by selecting the appropriate parameters.

- Blowing methods: The machine supports two methods of blowing fiber optics: stream method and piston method.

- Adjustable air head.

- Possibility of lubrication of the follower during blowing.

- Supplying the machine with one hose.

- Injection parameter registrations: effective cable force measured in Newton (N), fiber wear pressure (bar), injection speed (m / min), injection length (m), creating a graph during machine operation and the ability to print a report.

Recommendations & patents

DESCRIPTION OF WORK

Machines for blowing and introducing optical fibers

The fiber optic cable is inserted through a set of aluminum-rubber profile rollers depending on the outer diameter of the cable. Each roller has its own mechanical drive, which is transmitted by gears and a chain.

The rubber part of the roll is designed to prevent the cable from slipping when there are resistances that appear on long sections and bends of fiber optic routes. The groove in the rubber part profiled for the diameter of the cable wraps the optical fiber in 90% thanks to which we increase the force of fiber insertion in the follower tube. With the correct pressure setting of the cable rollers, the rollers perform the function of a clutch. If the pressure on the rollers is too high, the rollers forgive operator errors and do not damage the cable.

The driving force of the mechanical system of the roller assembly is a pneumatic gearmotor. Supporting the process of blowing the optical fiber into the follower tube, the head in which compressed air is fed plays an important role. The head is so-called reliable mechanical feeder turbine. The air head was constructed in such a way that compressed air fed and appropriately shaped to the repeater lifts the cable minimizing the friction of the cable against the internal walls of the repeater. Thanks to the lower friction, it is possible to feed the cable over much longer distances.

Each machine has a set of nozzles and rollers with supports for each cable diameter. Individual types of blowing machines produced by us support all types of optical fibers and microcables.

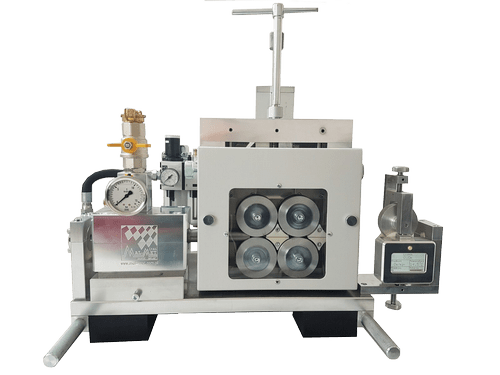

Earlier models

We sold the MAH-3 models in three versions

MAH-3

High power 3-17 mm

MAH-3 Uniwersal

All diameters on the market: 0.8-17 mm

Mini MAH-3

Microcanalization 0.8-6 mm