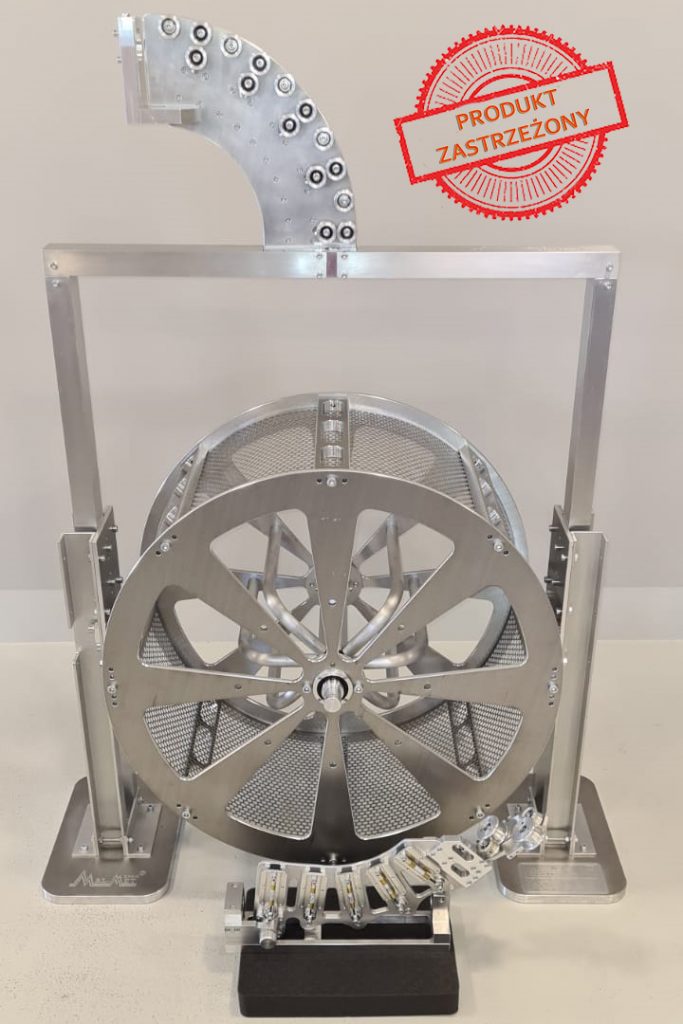

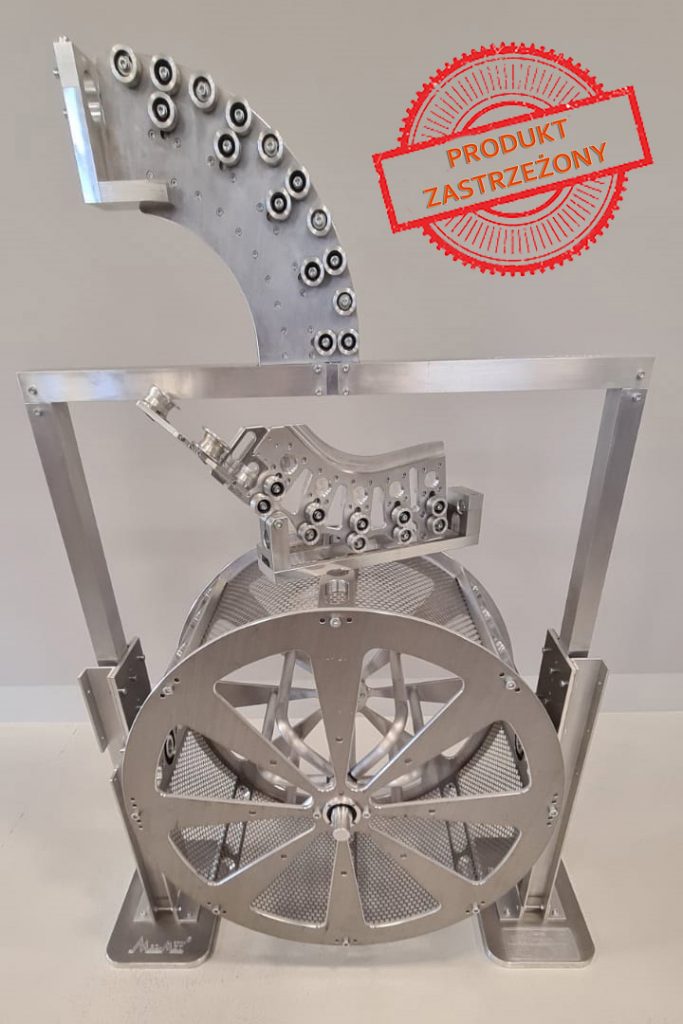

The device is designed to work with fiber optic cable blowing machines. It significantly improves the quality and comfort of work during looping when there is a need to store the cable between manholes. Several innovative solutions were used:

- The basket never comes into contact with the ground, thanks to which the cable is protected against dirt

- There is no need to pull the cord after winding it, the basket can be rotated so that the end of the cord is at the top, allowing it to be inserted into the blowing machine and the process continued

- At any time, the winding / unwinding process can be interrupted and the fiber optic cable pulled out. The elements are split over the entire length of the cable routing.

- The coiled cord can be left in the bin for possible transport. It is enough to screw the cover, which is both the top and the bottom of the device, depending on the location.

- All rollers are bearing, placed at appropriately selected intervals on guides, tightened with precise force by gas springs. This solution ensures very stable cable routing in the diameter range from 5mm to 16mm

The device does not require periodic inspections or special maintenance. If kept clean, it should work without failure for many years. All used bearings have been protected against solid dirt and moisture. We have created this device to facilitate your work and reduce the number of people needed for looping on fiber optic routes.