The above model will be equipped with:

– a smart touch controller

– two operation modes: manual – allowing for manual operation, which means that an operator controls settings during operation automatically – after entering of appropriate data and switching on automatic mode the machines controls the cable feeding process independently and with appropriate force and does not allow a fibre optic cable to be damaged.

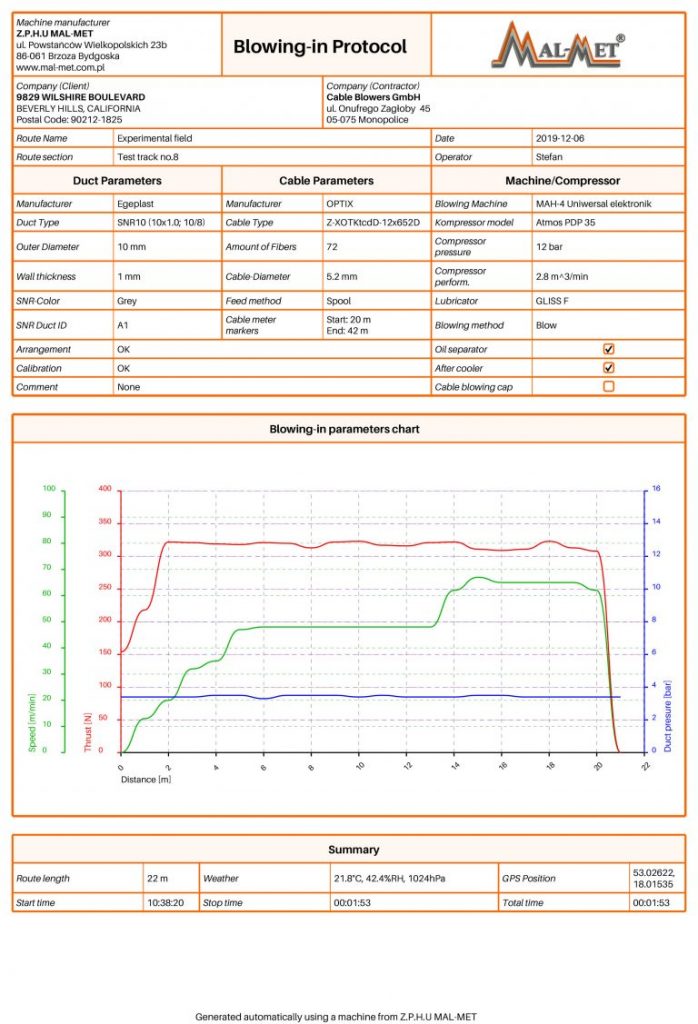

– recording of blowing parameters: cable pressing force measured in Newton (N), fibre optic carrying pressure (bar), blowing speed (m/min), blowing length (m) creation of a chart during operation of the machine

– GPS of the machine location on a map

– reading of weather parameters: temperature, atmospheric pressure (Hpa), humidity (RH%)

– wireless connection: machines with ancillary equipment such as a tablet, laptop, telephone etc., date and time

– a report on moulding is served through an Internet browser, which includes prepared information tables.

The machines can be equipped with 4 different models of heads

A micro head: as the name implies, these types of heads are used for moulding of micro cables.

A basic head: intended to cable blowing and micro pipes.

Y head: cables and pipe packages, possible blowing of another cable or pipe to the existing system with one or two cables in both directions with the so-called looping,

X head: cables and pipe packages, possible blowing of another cable or pipe to the existing system with one or more cables in both directions with the so-called looping.

Sample blowing report

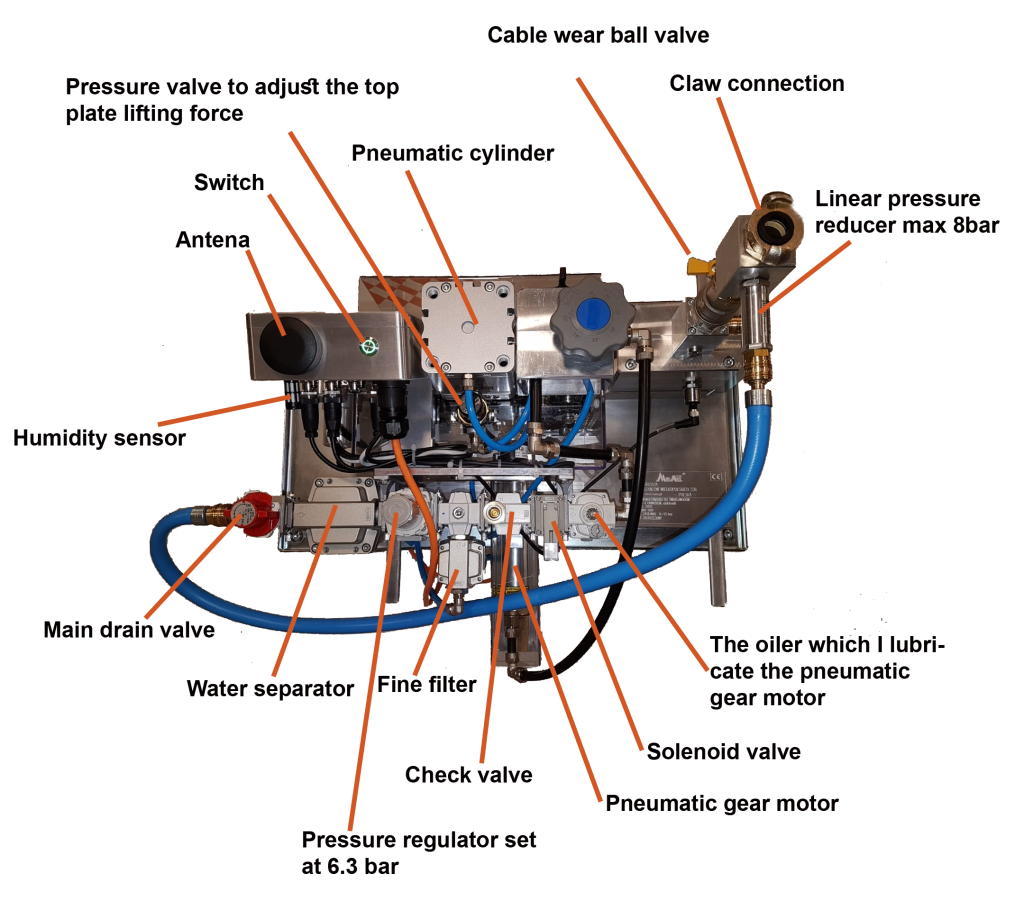

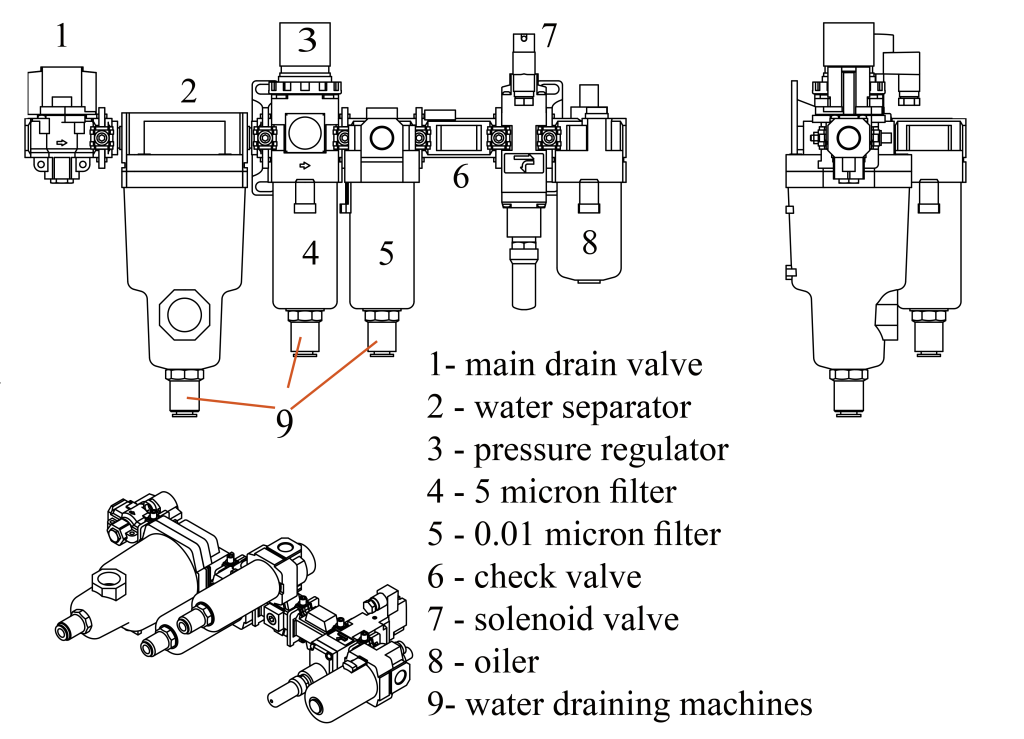

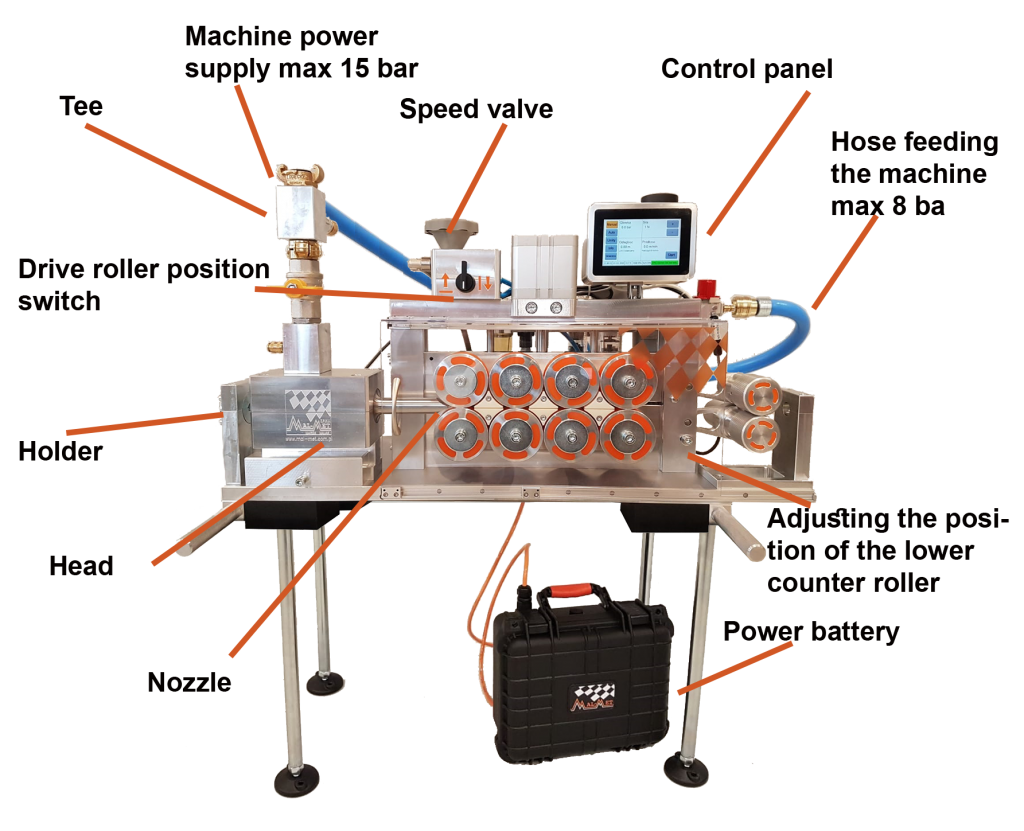

Construction of a blowing machine

Front view

View from above